1.Surface Preparation: It is essential to ensure that the contact surfaces between electronic components and the thermal pads are thoroughly clean. Any contaminants or impurities could adversely affect the adhesive properties and thermal conductivity of the pads. Therefore, surfaces must be cleaned meticulously prior to application.

2. Handling Large Thermal Pads: For large thermal pads, it is advisable to start handling from the center. This approach helps prevent uneven stress that could potentially deform or damage the pad. This precaution is not necessary for smaller sheets.

3.Removing the Release Liner: Begin by gently peeling the release liner from one corner of the thermal pad. Proceed slowly and steadily to avoid any damage to the pad. Minimizing direct contact with the thermal pad during this process is crucial to maintain its adhesive and thermal properties.

4. Applying the Pad: Proper alignment of the thermal pad with the heat sink and the electronic component is critical. Carefully place the pad and use a flat tool to smooth it from one side to the other, ensuring that no air bubbles are trapped under the surface.

5. Dealing with Air Bubbles: If air bubbles form during application, carefully lift one end of the thermal pad and reposition it or use a specialized tool to gently remove the bubbles. It is important to handle the pad delicately to avoid any damage.

6. Removing the Opposite Protective Film: After adhering one side, cautiously remove the protective film from the other side, taking care not to pull or introduce new air bubbles.

7. Securing and Curing: Once the pad is in place, apply suitable pressure to the heat sink to ensure it bonds well with the target surface. Allow sufficient time for the thermal pad to securely adhere. During this period, avoid any movement or disturbance to the assembly to ensure the effectiveness of the bond.

1. Impact of Thermal Pad Hardness on Thermal Performance:

When the contact surfaces are rough, the contact thermal resistance can impede heat transfer, manifesting as higher temperatures in the device while the heat sink remains cooler. Harder pads can only fill larger gaps, whereas softer pads under certain pressures can adequately fill finer gaps between interfaces, significantly increasing the contact area and thus reducing thermal resistance. This ensures efficient heat transfer from the device to the heat sink.

2. Choosing the Thickness of Thermal Pads:

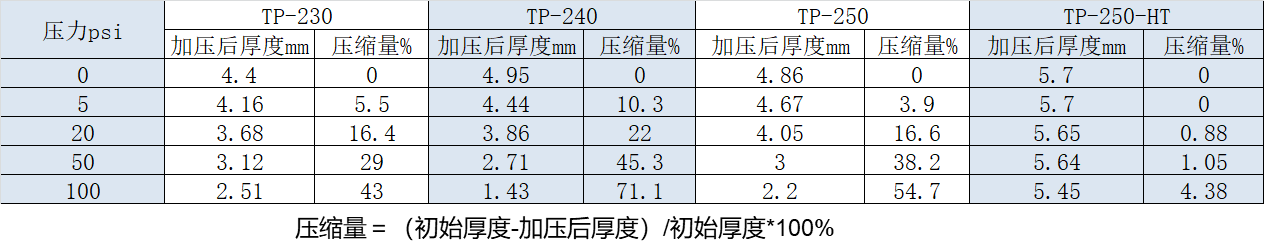

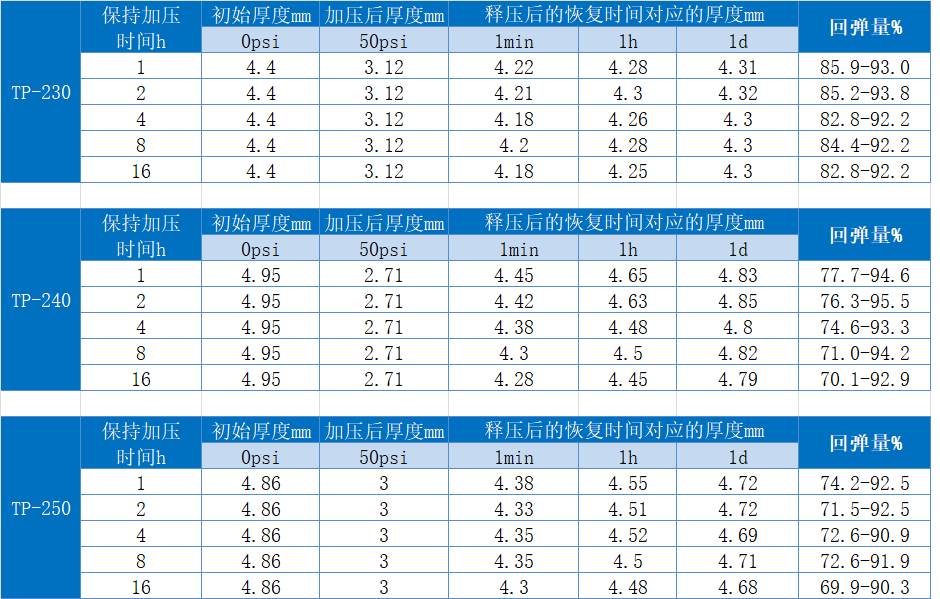

The thickness of the thermal silicone pads should be selected based on the specific application requirements, considering the gap and roughness of the device and heat sink interface, as well as the pressure the device can withstand. Typically, the selected pad thickness should be slightly more than the nominal gap size between the heat sink and the device. The general compression ratio of thermal silicone pads is about 10-20%, but Zhuoyu PAKCOOL® thermal silicone pads can undergo 30-40% compression deformation. A thicker pad allows for greater compression deformation under the pressure applied by fasteners, better filling the gaps between the device and the heat sink, thereby reducing contact thermal resistance and enhancing thermal conductivity.

3 . Selection of Thermal Conductivity for Thermal Pads:

Higher power dissipation and heat density in devices necessitate the use of interface materials with higher thermal conductivity. Chooyu PAKCOOL® thermal silicone pads offer a thermal conductivity range from 1.5 to 8.0 W/m▪K, catering to various customer needs.

If the heat sink has adequate volume and surface area, using a material with higher thermal conductivity can more rapidly reduce the device temperature, typically measured at the device’s solder joints to estimate the chip’s junction temperature. However, if the temperature difference between the device’s solder joints and the heat sink is small, further increasing the material’s thermal conductivity may not significantly improve performance, and higher thermal conductivity pads tend to be more expensive.

When the device's heat density is high and the heat sink's volume and surface area are insufficient, the heat capacity is too low and the heat exchange with the environment is not fast enough; even using a high thermal conductivity interface material will only minimize the temperature difference, and the heat sink will still be hot. In such cases, it is crucial to consider increasing the heat sink's volume and surface area, improving air circulation, or using active cooling solutions like heat pipes or liquid cooling plates to accelerate heat exchange and maintain the device's operation within a safe temperature range.

4.Adhesive-Backed Thermal Silicone Sheets:

The surface of thermal silicone sheets typically has some stickiness, so adhesive backing is usually unnecessary. Adhesive backing can increase the thermal resistance of the silicone sheet, thereby affecting its thermal performance.

Key Features of PAKCOOL® high Thermally Conductive Pad

|

PAKCOOL®TP-2xx series Thermally Conductive Pads possess excellent insulating properties, are suitable for die-cutting, fit for large-scale production, and do not require chemical reactions during manufacturing, making them easy to rework. However, the interface thermal resistance of Thermally Conductive Pads is typically higher than that of liquid thermal products, and they are more expensive, lack adhesive strength, and cannot return to their original thickness after prolonged use. Changes in the contact surface shape between the device and the heat sink may necessitate a redesign of the die-cut shape and/or thickness.

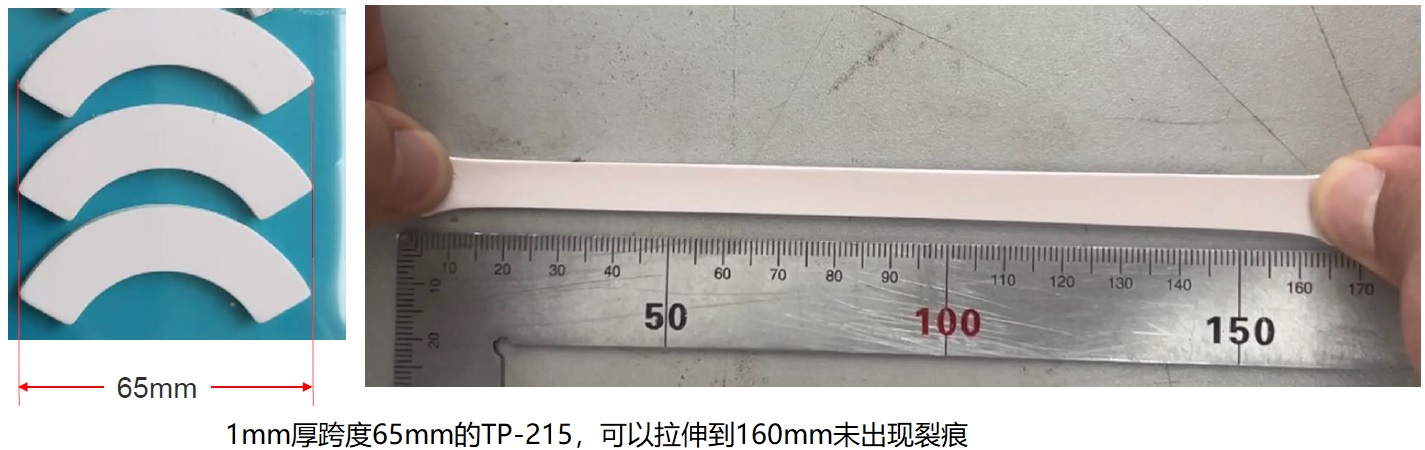

In the PAKCOOL® TP-200 series, the ultra-soft pads have a hardness lower than 60 (Shore 00) and can undergo up to 35% compression deformation. The high proportion of thermal fillers in high thermal conductivity pads makes manufacturing these ultra-soft pads with high thermal conductivity relatively challenging. Nevertheless, even high thermal conductivity products in the PAKCOOL® TP-200 series maintain a low hardness of up to 60 (Shore 00). Chooyu's PAKCOOL® Thermally Conductive Pads can protect pressure-sensitive devices due to their softness and significant compressibility, allowing a single pad to cover devices of varying heights. Due to their softness and ability to withstand significant pressure, using thicker pads can fill very small gaps, thereby reducing the contact thermal resistance between the pad and the device and the heat sink, enhancing the interfacial thermal transfer performance. Additionally, the softness and good resilience of Chooyu pads provide vibration protection for PCBs.

|

|

返回列表

返回列表