|

Product Name

|

Color

|

Thermal Conductivity(W/m·K)

|

Thermal Impedance@20psi,0.5mm(K-in2/W)

|

Thickness(mm)

|

Density(g/cm³)

|

Hardness@25℃(Shore OO)

|

Phase Transition Temperature(℃)

|

Volume Resistivity(Ω·cm)

|

File

|

|

PC-7630

|

Gray

|

3.0±0.1

|

0.34

|

0.3-5.0

|

2.95±0.05

|

50±10

|

42-52

|

≥2.0×1013

|

PC-7630

|

Packaging Specifications for PAKCOOL®Thermally Conductive Phase Change Paste

PAKCOOL®PC-54xx series is offered in a 1Kg, 5Kg and 20Kg barrel or 330mL, 55mL tube or customizable according to customer requirements.

Operating Guide for PAKCOOL® Thermally Conductive Phase Change Paste

1. Preparation and Storage Before Use: Thermally conductive grease can be stored at 2-8℃ for approximately 12 months. Before use, acclimate the product at 25°C for at least 4 hours to ensure the material reaches the ambient usage temperature.

2. Application Method and Process: The interface surfaces should be cleaned with alcohol to remove dust before thermal grease is applied on the surface.

During application, use a screen-printing process.After the material is applied between the component and the heat sink, it should be placed under appropriate drying conditions to cure into a solid phase-change layer, ensuring optimal thermal performance. For best results, the thinner the paste layer, the lower the interfacial thermal resistance, provided the interface gap is fully filled.

3. Unused Products: Any unused material should be tightly sealed for future use.

Typical Drying Conditions:For example, with a coating thickness of 0.025 mm (see table below) The below drying profile is a guideline recommendation. Conditions (time and temperature) may vary based on customer’s experience and their application requirements, as well as customer’s drying equipment, oven loading and actual oven temperatures.

|

Temperature

|

Time

|

|

25°C

|

48 h

|

|

70°C

|

60 min

|

|

150℃

|

10 min

|

-

1. 1. This product is volatile; proper protection and well-ventilated usage environments are required.

-

2. 2. Viscosity varies with the temperature, it's recommended to use in constant temperature conditions.

-

3. 3. Please refer to the product's Material Safety Data Sheet (MSDS) for safety details.

Process Characteristics of PAKCOOL® Thermal Conductive Phase Change Paste

Screen Printing Process

|

The material used for screen meshes is typically nylon. The thickness of the coating applied during the screen printing process is related to the mesh count of the screen. A lower mesh count means a larger diameter of the mesh openings, which results in a thicker coating under the same printing conditions. The table below illustrates how different mesh counts correspond to different coating thicknesses:

|

Mesh Count

|

Mesh Thickness(mm)

|

Coating Thickness(mm)

|

|

60

|

0.21

|

0.135~0.145

|

|

80

|

0.20

|

0.12~0.15

|

|

110

|

0.15

|

0.09~0.10

|

|

Packaging Specifications for PAKCOOL® Thermally Conductive Phase Change Pad

PAKCOOL®PC-76xx Series Thermally Conductive Phase Change Pads are adhesive-free and can be cut to size according to customer requirements.

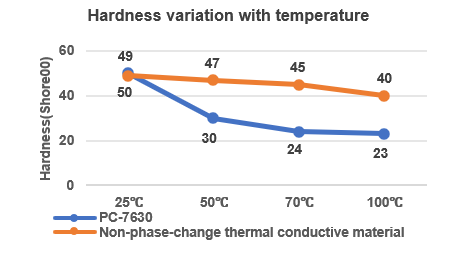

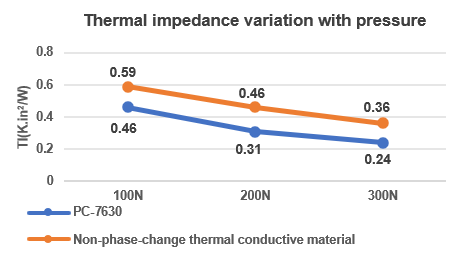

PAKCOOL® Thermal Conductive Phase Change Pad offers excellent stress-buffering capability

返回列表

返回列表